Description

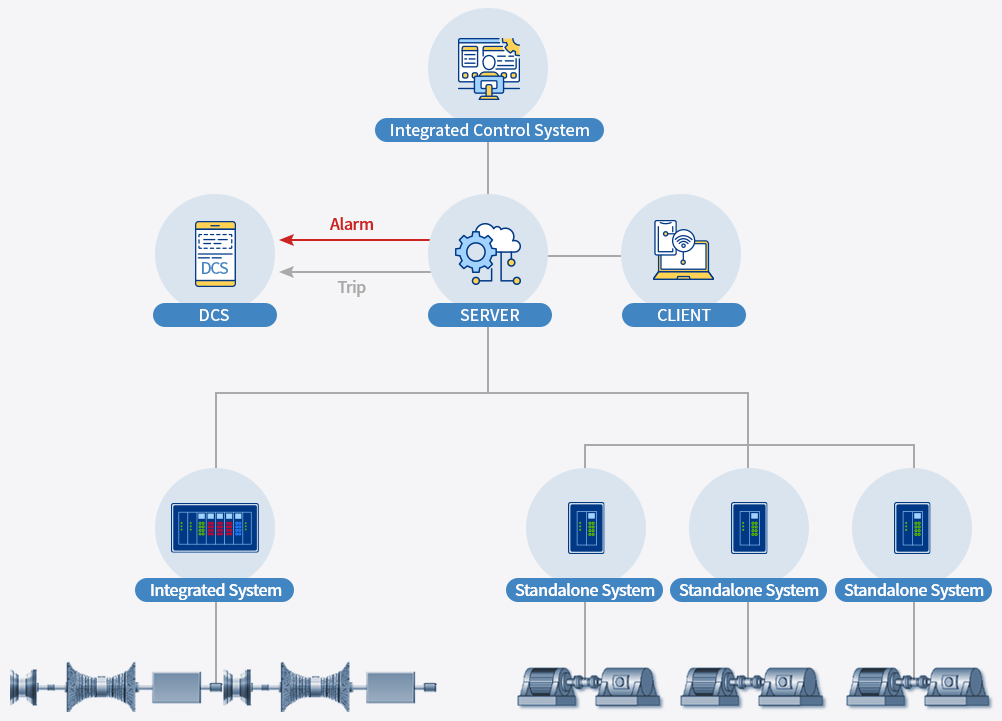

VMS is a vibration precision monitoring system for turbines and major rotating equipment. By monitoring the status of major facilities in power plants in real time, it is a system that detects malfunctions and abnormalities of facilities early and prevents serious accidents.

The vibration monitoring system is a system designed to monitor the state of the elastic rotating shaft using a sensor, and is mainly used to prevent damage to the rotating shaft due to excessive bending when passing dangerous speeds.

Features

-

Integrated (V-net 7000A): Traditional Rack type monitoring system

-

Standalone (V-net 7000B): Minimize noise through stand-alone type signal processing module

-

Real-time facility protection function provided

-

Compliance with API670 standard

-

Hot Swappable

-

Provides data through various communication protocols such as Modbus and OPC

-

Reflects speed and load conditions for each driving condition