With a team of young and passionate people

Our goal is to become the leader in providing the new-tech services in Vietnam and abroad

ON-LINE LEAK SEALING

We are the exclusive company in Vietnam authorized to provide the Under pressure on line leak sealing service of PETROSEAL company

View more

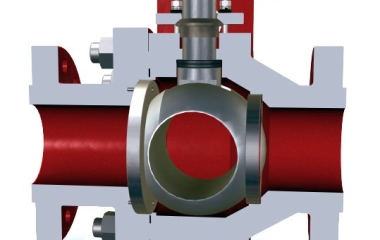

VALVE REPAIR

We are confident that we can provides Service packages for maintenance and repair of valves for any type of industrial valve.

View more

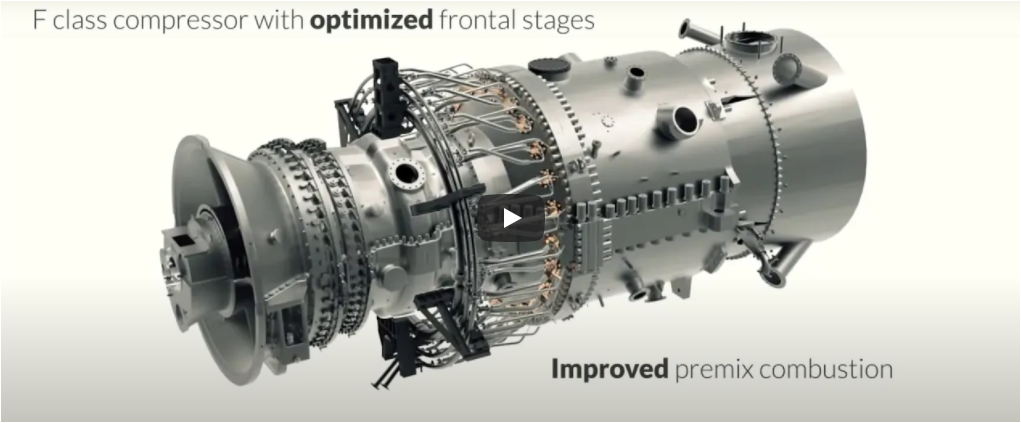

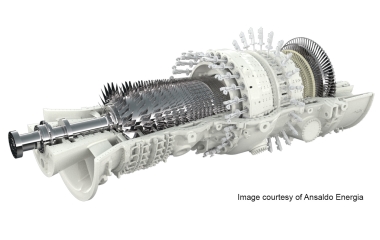

TURBINE REPAIR

With more than 10 years of experience of experts in the field of maintenance and operation of power plants, SIS provides overhaul services for power ...

View more

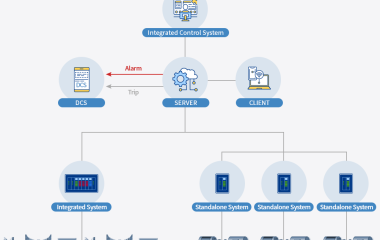

THE VIBRATION MONITORING SYSTEM

VMS is a vibration precision monitoring system for turbines and major rotating equipment. By monitoring the status of major facilities in power ...

View more

FLOWMETERS

We provide a powerful source of Turbine Flowmeters and Electronics for a wide range of flow applications.Our available products include: Industrial ...

View more

STEAM TURBINES AND SPARE-PART

Our partners have more than 100 years of experience in the design, manufacture and installation of steam turbines, with more than 700 units worldwide ...

View more

CONTAINER FILTERS SEA WATER INTO DRINKABLE WATER

A water treatment system consisting of an ultrafiltration, reverse osmosis and ozonation module are used in combination, depending on the quality of ...

View more

INDUSTRIAL VALVE

As for valves, we not only provide products, but also provide valve repair services.

View more

SIS CAN UNDERTAKE EPC CONTRACTS

EPC service (general contractor) of Saigon Industrial Service Company provides throughout the investment project formulation, technical design, ...

View more

BIOMASS ELECTRICITY

Biomass power generation is more and more popular because of its high energy efficiency, environmental protection and other advantages. This is a ...

View more

THERMAL POWER USE NATURAL GAS

Liquefied natural gas power remains an important part of Vietnam's energy transition story. Investors continuously show a strong interest in this ...

View more

WATER TREATMENT TECHNOLOGY

Saigon Industrial Service has been cooperating with leading corporations and companies in Vietnam and in the world in the field of clean water ...

View more

TIDAL ENERGY

Many countries in the world have used energy from the sea. Currently, about 100 companies worldwide are working on converting energy from the ocean ...

View more

SOLAR FARM

EPC service (general contractor) of solar power projects (solar farm, rooftop, ..) of Saigon Industrial Servive Company (abbreviated as SIS) provides ...

View more

PETROSEAL TRAINING COURSE 2023

On March 28th, 2023, SIS has collaborated with Petroseal to initiate an extensive training course. The goal of this training course is to improve the ...

NEW WORKSHOP IN PHU MY TOWN

In order to improve the maintenance capacity as well as expand the field of operation, Saigon Industrial Service have started the construction of a ...

Những "siêu dự án" LNG tỷ đô sẽ được khởi công trong năm 2021

Với tổng vốn đầu tư hàng tỷ USD và quy mô hàng nghìn MW, các dự án điện khí này kỳ vọng sẽ góp phần phát triển ...

NĂNG LƯỢNG TÁI TẠO VIỆT NAM ĐỨNG TOP ĐẦU TRONG SỐ CÁC THỊ TRƯỜNG MỚI NỔI

Australia đứng đầu chỉ số, với 89% công suất đang được xây dựng là điện gió, điện mặt trời, hoặc điện sinh ...

PHƯƠNG PHÁP XỬ LÝ RÁC THÀNH ĐIỆN NĂNG

Xử lý rác là vấn đề quan trọng và nan giải không những ở Việt Nam mà còn trên toàn thế giới, các quốc gia làm ...

CÔNG TY CỔ PHẦN DỊCH VỤ CÔNG NGHIỆP SÀI GÒN TÌM HIỂU ĐẦU TƯ CÁC DỰ ÁN SẠCH CỦA GENCO2

Ông Nguyễn Anh Vũ, trưởng Ban Quản lý Điện và ông Nguyễn Thanh Hùng phó trưởng ban phụ trách xây dựng đã trình bày ...

PHÊ DUYỆT ĐỀ ÁN PHÁT TRIỂN THỊ TRƯỜNG ĐIỆN, THAN, KHÍ CẠNH TRANH

Phạm vi Đề án bao gồm 3 phân ngành năng lượng (than, khí và điện lực) giữ vai trò quan trọng, chủ chốt trong chuỗi ...

NỖI LO ...THỪA ĐIỆN

Cắt giảm điện vì thừa nguồn Trước đó ít hôm, nhiều doanh nghiệp lớn trong lĩnh vực năng lượng tái tạo đã phải ...

TẠM DỪNG CÁC DỰ ÁN THỦY ĐIỆN NHỎ TRONG QUY HOẠCH

Bộ Công Thương cũng đề nghị, trong thời gian tới, các địa phương cần đẩy mạnh rà soát việc vận hành khai thác ...

THỦ TƯỚNG YÊU CẦU RÀ SOÁT CÁC VẤN ĐỀ LIÊN QUAN ĐẾN PHÁT TRIỂN ĐIỆN MẶT TRỜI

Ngay từ tháng đầu năm 2021, EVN đã phải xây dựng và thực hiện phương án cắt giảm nguồn điện mặt trời, cũng như ...